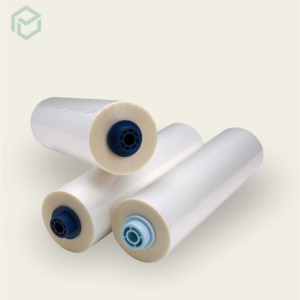

Laminated Rolls

Safeguard your products and streamline your lines with Laminated Rolls. Designed for high-speed converting and packing, these rolls offer exceptional barrier properties against moisture, oxygen, and more. Ensure product freshness and extend shelf life while maximizing production efficiency.

Detailed description of the Product

- Laminated rolls are a versatile packaging material that can be used for a variety of applications, including food packaging, industrial packaging, and retail packaging. They are made by combining multiple layers of different materials, such as paper, film, and foil, to create a strong, durable, and moisture-resistant barrier.

- Laminated rolls can be customized to meet specific packaging needs, including size, thickness, and material composition. They can be printed with high-quality graphics and branding, enhancing product appeal and brand recognition.

- Laminated is a cost-effective and efficient packaging solution. They can be easily cut and sealed, reducing labor costs and minimizing waste. Additionally, they can be recycled, making them an eco-friendly choice